Hands on experience, is the only true way to learn.Ĭompetency in math, science, and computer skills are necessary. Skilled technicians of the CNC software company generally provide training to those new users of CNC machines. During that time, they need software technicians who will provide knowledge and support.īefore using a CNC Machine, beginners need to spend time gaining expertise with CAD software. New CAD designers need a minimum of two weeks to become familiar with CAD software. Each operator has different skills and needs. There is no single CAD software program for everyone. Without a positive experience with this software, the entire CNC software program is doomed. It can take a long time to master CAD programs. Because it is the first and the one they will be using the most, this one must be user-friendly. This is the first of the three software products they need. These are sent to machines telling them what to do.įirst, beginners need to find CAD software they can use comfortably and grow with. Further, they need to be able to use CNC software to convert the designs they have accessed in the templates on the software or created using the software to g-code. It is imperative that beginners are able to use CNC software. They need an understanding of the machines which receive their cd.

FREE CAD SOFTWARE FOR CNC ROUTER HOW TO

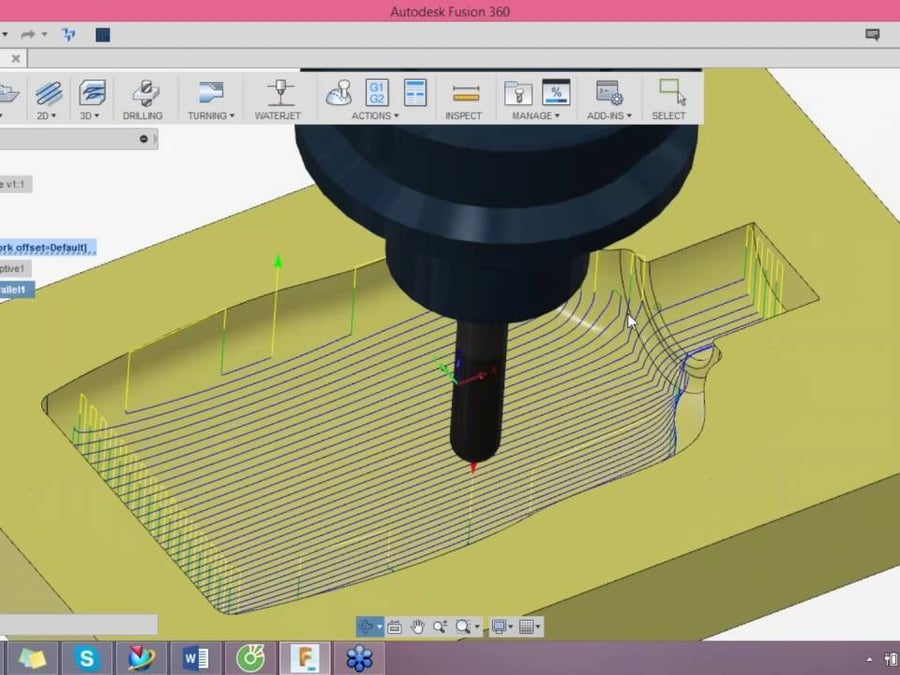

The best CNC software for beginners allows users to know how to use the hardware on which the CNC software is loaded. What are the basics beginners need to know? Tools The precision machinery performs tasks like slicing, cutting, grinding, milling, and drilling into and around material.īesides parts and specialized pieces, CNC machines can produce signs, etchings, engravings, and unique products to suit clients’ special needs. These can be fabricated from a variety of materials including wood, metals, and plastics. So what is the final product? CNC machinists use machinery controlled by CNC software to produce parts and tools. Essentially, this means typing commands and having specialized machines execute it immediately. CAM puts it into a language your machines can understand and creates a g-code.

In a nutshell, CNC takes the data created by CAD. Also built into your CNC software is a controller. The speed and feed calculator provides this input. The machine also needs direction about feed and machine speed.

The machine needs information about what work needs to be done. This is what your CNC machine requires to run its passes. If you can envision a product, CNC machines can create it.ĬAM software takes the CAD drawing file and creates a g-code. Using CNC software, the “blueprints” for what you want your machine to produce are created. CNC machines replace or work with existing manufacturing processes.įirst, operators use Computer-Aided Design software to create a design or utilize the templates provided on the CAD software. As technology continues to change, these automation processes are vital in helping businesses to scale and produce more cost-effective products for customers.ĬNC has an effect on every facet of manufacturing. It makes the products of manufacturing more accurate and consistent. Working in place of or in tandem with other manufacturing processes, CNC software improves automation. Below we're giving some information on the best CNC software for beginners. While this all sounds complicated, there are a few things to know about CNC software. In fact, it has existed since the early 1970s when it was called Numerical Control or NC programming and flexibility. The design is then translated into a language the machine understands by a Computer-Aided (CAM) software program.Ĭomputer Numerical Control is not new.

The design for what the machine creates is Computer-Aided Design (CAD) software. In specific, its programming software helps machines understand function and design. More often than not, CNC software works to enhance or automate the manufacturing process. Instructions reach the tool or machine via a computer. Computer Numerical Control, or CNC programming, software creates program codes and instructions, which are used to run a CNC linked tool.

0 kommentar(er)

0 kommentar(er)